Spot Welding

Resistance welding comes in so many forms. The most commonly used forms of resistance welding include spot, projection, and seam. In this article, we will specifically focus on spot welding. It is one of the major services that Contract Manufacturing Specialists of Ohio offer. You will never go wrong when you use our services for spot welding. In the meantime, let us take some time to learn a few things about spot welding.

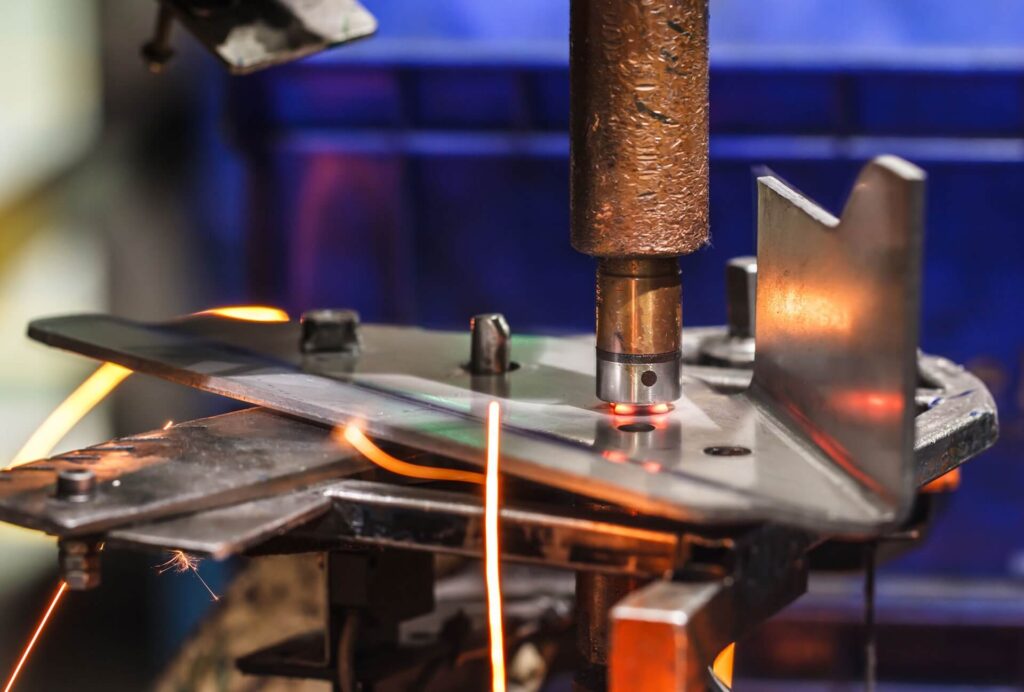

If you want to achieve consistent quality in the production of spot welding, you need to understand three principles. These include the electrical current, the time, and the pressure (mechanical pressure – electrode force). The three factors are closely related and the operator has to balance them for him to produce a quality bond two metallic pieces with consistency. Electrodes conduct the current to the two metal pieces to be fused when they are forged together.

The weld cycle should first build adequate heat amount through the electric current and the amount of time that the current is applied to increase a small volume of the molten metal from the working pieces t be bond. Thereafter, the molten metal is allowed to cool while still under pressure from the electrodes until it sets a maximum strength that the metal allows in order to hold the parts together. On the welder, we refer to this as the hold time.

If you change any of these parameters without properly adjusting the others, it can lead to a poor bond. For instance, if you increase the current with an inadequate amount of pressure, it will lead to an excess weld splash. Conversely, changing the pressure without correspondingly changing current and time may also lead to poor welds.

There are so many aspects of the machine set-up that greatly affect the welders’ kva resistance settings. When a part is large and can’t be fit into a short set of the spot welders’ arms, you may have to change or extend the arms to be able to accommodate the part’s depth. A spot-welding machine that has long arms for the deep entry of the products that need to be bonded will have a higher electrical impedance than the same kva machine with a shorter set of arms. The electrical impedance reduces the resistance welder efficiency greatly.

The electrical impedance measures the opposition that an electric circuit presents to the passage of current once you apply a voltage. When it comes to resistance welding, it’s the increase in resistance due to the higher distance and obstacles that the current requires to flow through to arrive at its destination i.e. the welding electrodes. The spot-welding process is exceptionally incredible and a perfect suit for high-volume manufacturing and is flexible for most alloys and metals. The companies that specialize in this process utilize a micro-resistance spot welding link or connecting two metal parts. The application of mechanical pressure and an electric current is the setting stone for the whole process.

The primary attribute of spot welding is the fact that there is a high energy concentration to the spot within a concise time of approximately ten milliseconds. In such a way, the welding is accomplished resulting in excess heating to the other parts of the sheet. Companies that offer specialized micro spot welding services give assistance and guidance to make sure that you choose the correct equipment for your application.

You may think that the micro resistance spot welding industry isn’t lucrative but it is indeed. There are so many examples of how to apply micro-joining and micro-welding in the industry. The technique is highly prevalent in the automobile manufacturing sector. You will get so many parts on the auto-ignition module, anti-lock braking system, battery pack connector, and the automotive sensor printed circuit board to name a few. The equipment that Orthodontists use is the other example of the application of small-scale welding equipment.

Spot welding has several limitations and benefits. Spot welding has so many limitations and benefits. The first advantage of spot welding is that it utilizes energy effectively with minimal pollution. It is possible to carry out mass productions within short cycle times. The process is completely automated. In some instances, you can weld dissimilar metals and multiple sheets. When you look at the limitations, most metals can be welded easily. However, the application is limited to thin materials. The weld spots don’t form a continuous seam and hence the tensile strength may be lower.

For a series of in-line soldering, you only need to consider the fine spot-welding heads. When dealing with automated applications, you have to use them with an air actuation system to attain a high-speed performance that is reliable. You will indeed get precise results that are consistent as per expectations. The system guarantees you a fast and dynamic response that begins the welding controls at the exact minute when the stated electrode force is applied on the workpiece.

The ideal applications of fine spot-welding heads are miniature lamps, switch contacts, terminal connections, electrical connectors, battery pack assembly, and electro-mechanical parts. Whatever your requirements or your application, this welding technique is unmatched because of its durability and high performance. The equipment delivers a truly unique solution that otherwise is impossible to difficult in joinery applications.

In addition to spot welding, there are other techniques that you can use in joining metals together. You can use them to join steel to steel and metal to metal. The common ones include wire feed welding, art welding, gas welding, and tig welding. It is good to have the definition of each so that you don’t confuse with spot welding.

Wire feed welding is also referred to as MIG welding. The correct terminology is Gas Metal Arc Welding or GMAW. As you use this technique, you hold a gun or torch in the hand and then squeeze a trigger. Once you squeeze the trigger, the wire that is inside the torch will begin to come out. You will then point the wire on the metal that you would like to weld.

The technical term for arc welding is MMAW or SMAW. This is Manual Metal Arc or Shielded Welding. This time around, you will be using an electrode which is just the length of a filler wire which is averagely one foot long and covered in flux. As you continue using it, the rod up the flux will burn off to create a shielding gas that protects the weld.

Tig welding is a very delicate and fine welding technique. In this case, you will be holding your torch on one hand while using the filler rod in the other hand. The idea here is that you will slowly feed the filler rod into the welding as you continue. It is possible to weld with Gas Tungsten Arc Welding, GTAW or TIG without using the fuller rod or just melting the two metal bits together. The process is referred to as fusing where you use the heat that comes from the arc you are melting to fuse the metals together.

The last technique, which is the focus of this article. As we asserted before, the technique is often used in sheet metal fabrication. In a nutshell, you place the two metal pieces that you want to join between the electrodes on the arm ends of the unit. They are brought together and the welded section is placed between the points. It only takes one second it so to accomplish the whole process. It is just a buzz and it will be done. Excellent examples of the things that you can spot weld are toolboxes. There are several other types of metal welding including thermite, ultrasonic, and friction. For the best spot-welding services in the United States, you need to check out at Contract Manufacturing Specialists of Ohio offers.

The company commands the largest customer base when it comes to all forms of laser cutting and metal fabrication projects. You can get your name on this list by simply consuming our contract manufacturing services.

Our core offerings and services at Contract Manufacturing Specialists of Ohio includes, but is not limited to, the following:

We service multiple cities throughout the state of Ohio. We provide all the services listed above, and much more in every city throughout Ohio.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.