Laser Cutting Process

Laser cutting is among the processes that have reported a high level of popularity in recent years. The applications and benefits of most laser-based processes are similar. The reason is that a single laser machine can perform several processes. As a result, it can be hard to tell the one that is best for your business. To simplify this concept, our article explores the laser cutting process in deeper detail. It is good to understand the laser cutting process, the various types, its advantages, and where it is applicable the most.

What is Laser Cutting

Laser cutting, as the name suggests, is the use of a laser beam to cut material. You can either do this to trim down the material or cut it in complex shapes that the more conventional drilling tools will struggle with. The laser cutting process has so many similarities with engraving and drilling. The later entails creating thru-holes in materials or dents, like engraving that is used in the later process. Essentially, the holes and dents are cuts and you will always find laser machines being used for engraving and drilling too.

Using the lasers, you can cut a broad range of thickness sizes and materials. Therefore, it becomes an adaptable and handy process for anyone. The best company to help you implement such a project is the Contract Manufacturing Specialists of Ohio.

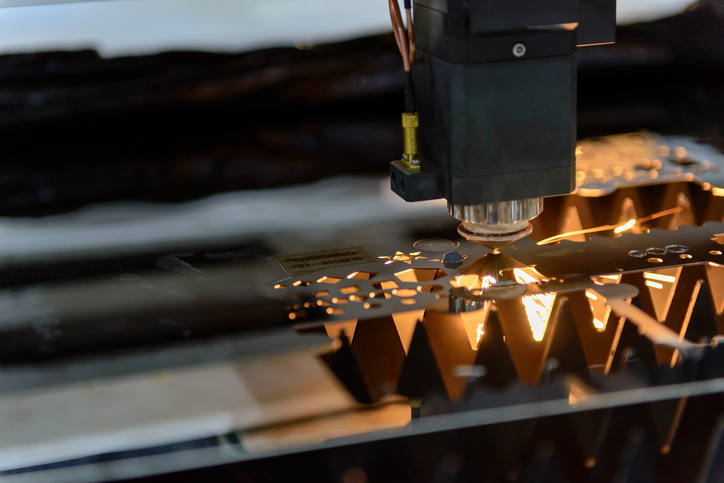

For this process to work, you need a precise and focused laser beam to run through the material that you want to cut. The laser cutting process delivers a smooth and accurate finish. The beam initially pierces the material with a hole at the edge. The beam will then be continued along from that point. Essentially, the laser will melt the material that it runs over away, and hence it is more of melting than cutting. Therefore, it can cut materials that range from clothes to gemstones like diamonds and tougher metals.

You can either apply a continuous wave bean or pulsed beam for the exercise. The former works continuously while the latter is delivered in a pulsed beam. The designer can control the intensity of the beam, heat output, and length depending on the material that you are working with. You can also use a special lens or a mirror to focus the laser beam further. The good thing about laser cutting is the fact that the process is highly accurate. The level of control that the technique offers is quite amazing. You can even use the later cutting process to achieve slits that have a small width of 0.1mm.

How the Laser Cutting Process Works

As we said, the laser beam is a column of an extremely high-intensity light, color, or a single wavelength. In the case of the typical CO2 laser, the wavelength is found in the Infra-Red section of the light spectrum and hence invisible to the human eye. The beam is just approximately 0.75 inches in diameter while traveling from the laser resonator that creates the beam vial the beam path of the machine. You can use several beam benders or mirrors to bounce it in various directions before finally focusing it onto the plate. The focused laser beam will go via the bore of a nozzle before hitting the plate. Compressed gas such as Nitrogen or Oxygen also flows the same Nozzle bore.

You can use a special lens or a curved mirror to focus the laser beam and this happened on the laser cutting head. The beam should be focused precisely so that the density of the energy and shape pf the focus spot are consistent and perfectly round, and centered on the nozzle. By focusing the huge beam down to one pinpoint, there is an extreme heat density at that spot. You can think of utilizing a magnification glass to focus the rays of the sun on a leaf and how it can start a fire. From here, think of focusing 6KWatts of energy on a single point and just imagine how hot that point will get.

The high-power density results include rapid heating, complete or partial vaporizing, and melting of the materials. When you cut mild steel, the laser beam heat is sufficient enough to start off the typical ‘oxy-fuel’ burning torch. If cutting aluminum or stainless steel, the laser beam will melt the material and then uses high-pressure nitrogen to blow out the molten metal of the kerf.

On CNC laser cutting, you move the laser cutting head over the metal plate in the desired parts’ shape hence cutting the part out of the plate. The capacitive control system is used to maintain a highly accurate distance between the plate that you are cutting and the end of the nozzle. The distance is crucial as it determines the position of the focal point relative to the plate surface. You can affect the cut quality by lowering or raising the focal point from just above the plate surface, just below the surface, or at the surface.

There are so many other parameters that also influence the cut quality. When you control all of them correctly, laser cutting turns out to be a reliable, stable, and very precise cutting process.

Why Use Lasers for Cutting

The applications of lasers are diverse and one of them is cutting metal plates. The laser cutting process is highly accurate on aluminum plate, stainless steel, and mild steel. It yields an excellent cut quality, small heat affects zone and small kerf width. It makes the cutting of small holes and intricate shapes possible.

You could be knowing that the term ‘LASER’ is an abbreviation for Light Amplification by Stimulated Emission of Radiation. You could be wondering how light can cut through a material like steel. There are different types of laser cutting and some of them include;

This laser cutting process is attained with the aid of a gas laser. This gas is a mixture of carbon dioxide that is stimulated electrically. In most cases, CO2 cutting is used on non-metallic materials because their wavelength is 10.6 micrometers.

The technique utilizes the neodymium-doped yttrium aluminum garnet (nd:YVO) and neodymium-doped yttrium ortho-vanadate (nd:YVO) lasers. The above crystals belong to the solid-state group of lasers and have a wavelength of approximately 1.064 which resembles that of fiber lasers. It means that you can use them for both non-metals and metals.

This laser machine is manufactured from very expensive pump diodes which is very expensive when it calls for a replacement. This typically takes place after using the laser for 8,000 to 15000 hours. Besides, the lifespan of the crystal that is used is much shorter than the fiber laser one.

Suppliers use fiber laser to execute this type of cutting and an excellent example is the SPI Lasers. Similar to the crystal method that we mentioned above. The fiber lasers also go beyond the solid-state.

The ‘seed laser’ creates a beam that is thereafter amplified using pump diodes and glass fibers. Their wavelength is also similar to the one above, 1.064 micrometers. The implication is that the fiber laser beam is approximately 100 times greater than the one of CO2 equivalent when dealing with the intensity. Besides, they can work with both metallic and non-metallic materials.

The fiber tends to be the most useful process among the other types of laser cutting processes. In addition to the other benefits that we mentioned in this article, fiber laser requires cheaper replacement parts, is maintenance-free, and its life span is much longer i.e. close to 25,000 hours of use.

Contract Manufacturing Specialists of Ohio focuses on the best laser cutting processes. The company can complete any type of cutting with a high level of precision. Our laser machines are great at working on a broad range of materials with highly efficient production rates and speed. You can be sure of getting a highly efficient industrial applications from the brand.

The company commands the largest customer base when it comes to all forms of laser cutting and metal fabrication projects. You can get your name on this list by simply consuming our contract manufacturing services.

Our core offerings and services at Contract Manufacturing Specialists of Ohio includes, but is not limited to, the following:

We service multiple cities throughout the state of Ohio. We provide all the services listed above, and much more in every city throughout Ohio.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.