CNC Machining

We are living in a world where technology is taking over, some of those things that were done manually a while ago are now changing. Computers are now taking over and driving the technology change that is sweeping across the world.

Computers are now taking over everything meaning the days of doing things in the usual ways are now getting behind us. Industries, in particular, have been the greatest beneficiaries of this technology. A while ago, you would walk into an industry and find people doing things in an old-fashioned way.

However, with the emergence of a computer that is now changed, people are now adopting the use of computers and other machines. One of the ways through which computers have brought transformation to industries is by CNC Machining.

CNC Machining is what informs this discussion today. We are going to look at it in detail and see what you need to know about the same. If there are any benefits from the same, we are also going to discuss them and offer you quality information in the same area.

CNC Machining

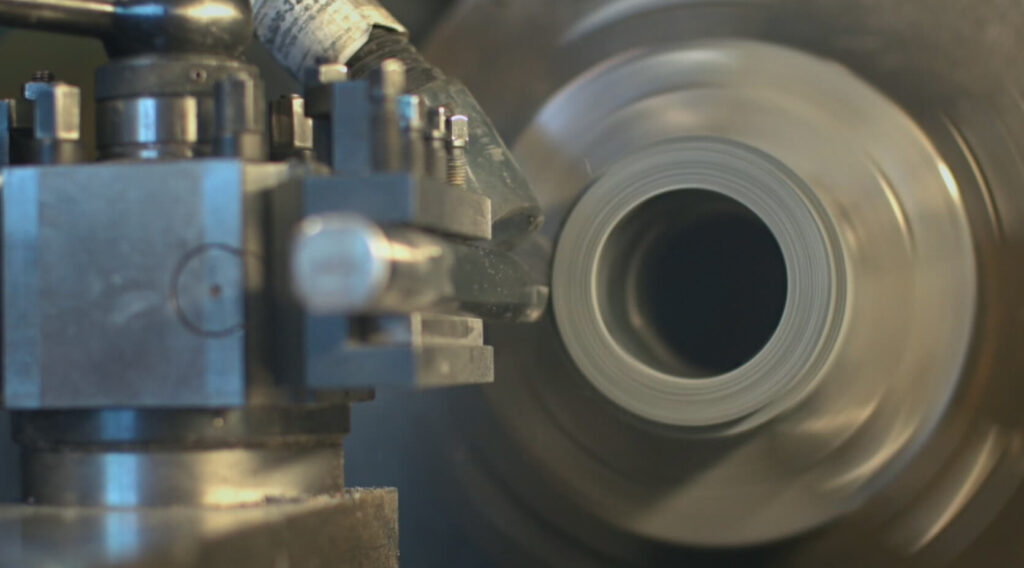

This is a process that is used by manufacturers in the production of machine parts. To make this process possible, numerical computer machines are used to make this process possible. A CNC machine is a machine that uses computer numerical control over machine tools like routers, leathers as well as grinders.

Computer numerical control is a little bit different from the standard pc with regards to the software used to control the machines. The CNC software is individually and specially designed using a G code. A G code is a specific computer language that users use in commanding the machines and controlling things like speed and feed rate among others.

There is specialized software which is used in driving the machining. The G code language allows precise control of coordination, among other things. There is a G code infused software that sits within a computer looking like a sophisticated desktop.

Once the software is well installed in place, it will only need one person who will do the controlling over a computer. This single control will be equivalent to several operators and lathes. This computerized machining method is capable of achieving reaches, holds, among other things.

This software or method is capable of doing some of those things that humans cannot do. With its usage, there is a very high level of accuracy and very little room for error. If you are looking to carry out your industrial machining procedures in an efficient way, then this is the way to go for you.

The fact that industries need larger metal and plastic parts means that CNC machining is such an excellent idea for manufactures. These plastic and metal parts come in as very sophisticated pieces making it so hard for manufactures to handle them using human input.

Advanced machines with up to around five-axis which perform similarly with the capacity to turn and flip apart. The Z-axis, for instance, moves up and down. CNC machines make it possible to automate those jobs which require several cuts.

A router which resembles the drilling equipment turns the cutting implement. Whereas all of a router bit cuts the material, a true bill bit only cuts at the tip. The CNC machining programming incorporates all the precise high-speed movements which are required to produce the objects, and it also creates room for detailed customization.

The fame of CNC machines has increased in recent years as it is becoming the best option in fabricating plastic as well as metal parts. The biggest benefit of this machining process is that it allows the manufacture to come up with more complex parts that would have otherwise be impossible to create under normal circumstances.

When it comes to typical production, many industries and manufacturers look for CNC machining because of its many benefits.

Between CNC machining and conventional machining which is better

One clear thing is that CNC machining and conventional machining all seek to achieve the same goal. Other than that, these two procedures also start from the same place where they have large chunks of plastic or metal that they need to shape into parts.

The way these two methods are more or less the same; the only basic difference between them is how they work. The aspect of automation versus manual is what makes the difference these two ways of machining.

However, CNC machining has the edge over the other method in so many ways, like speed and accuracy, something that makes most manufactures to choose them over the conventional methods.

As a manufacturer who has never used CNC machines, you may need to know if they come in with any benefits. If possible, you need to look at these benefits and compare them to those conventional machining and see which one is better than the other.

For larger companies, CNC machining is, without a doubt, the best option if you are looking to get the best results out of this process. We are going to look at the advantage of this machining procedure in detail and see why you need to select it over the other.

Benefits of CNC machining

If you have ever worked with people, then you must have encountered human errors. In some cases, these errors can come in way too costly when they occur. Even though you might try to remind your employees to minimize these errors, that might fail to happen.

Some errors happen even when they are not planned for, and when they do, they cost a lot. This is one of the reasons why you need to go to CNC machining. With this mode of doing things, there is so much precision that these machines bring when you use them.

They do not leave any room for errors when you choose to use them. If you are looking for maximum accuracy, then that is what you will get from CNC machining.

One of the things that you will never get from human power is working around the clock; this will never clock. People will get tired at some point, and that means work will have to stop. In some cases, some of them might even be lazy, meaning you might not get the best out of them.

When you turn to CNC machining, the case is entirely different. You can use the system in many ways, as you may please. The machine is capable of working during the day and night or just at any given time that you need.

The only time that you will have to stop these machines is when you have to repair and service them. With this happening once in a while, it means you will have to get the best output from these machines at all times.

There is one thing about CMC machines that cannot be compared to human input. When these machines are used well then, their output is nothing compared to what humans can produce. The machines are capable of producing any size or shape of the material you need.

This should be one of the greatest benefits of CNC machining compared to the other forms of machining. With CNC machining, you need very least or little workforce to operate the computers. This is unlike in the case of conventional machining, where you need so much workforce to make the process of machining possible.

This, when looked at from a different perspective, means you reduce your production cost. A reduction in production cost means you will end up making more profits in the long run.

If you are in the industry, then CNC machining should be one option you need to consider in your machining process. With so many benefits from above, CMC Machining is the best option compared to the conventional machining method. If you need the best and most genuine machines, Contract Manufacturing Specialists of Ohio will give you the best service ever.

The company commands the largest customer base when it comes to all forms of laser cutting and metal fabrication projects. You can get your name on this list by simply consuming our contract manufacturing services.

Our core offerings and services at Contract Manufacturing Specialists of Ohio includes, but is not limited to, the following:

We service multiple cities throughout the state of Ohio. We provide all the services listed above, and much more in every city throughout Ohio.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.